X-Rite's i1 Display & Projector Calibration Solutions provides a new level of perfection and value for the most demanding Color Perfectionists and Imaging Professionals for the highest level of color accuracy in the industry.

X-Rite delivers a new family of i1 Professional Color Management Solutions. The bar has been raised higher than it’s ever been to deliver a range of incredibly comprehensive, versatile and accurate color measurement, calibration and profiling solutions.

Color Perfectionists know that calibrated devices and systems are a critical and essential part of a successful, efficient and creative workflow. Whether you are looking for a solution to calibrate your displays, i1 solutions have long been the professional’s choice for exceptional color matching results.

Each i1 Pro Professional Color Management Solution combines world-class hardware; delivering the ultimate professional level color management solutions for imaging pros.

Whether you’re choosing a colorimeter or spectrophotometer for your displays calibration, you’ll be assured that you are getting world class devices designed to maximize your profitability, efficiency and accuracy.

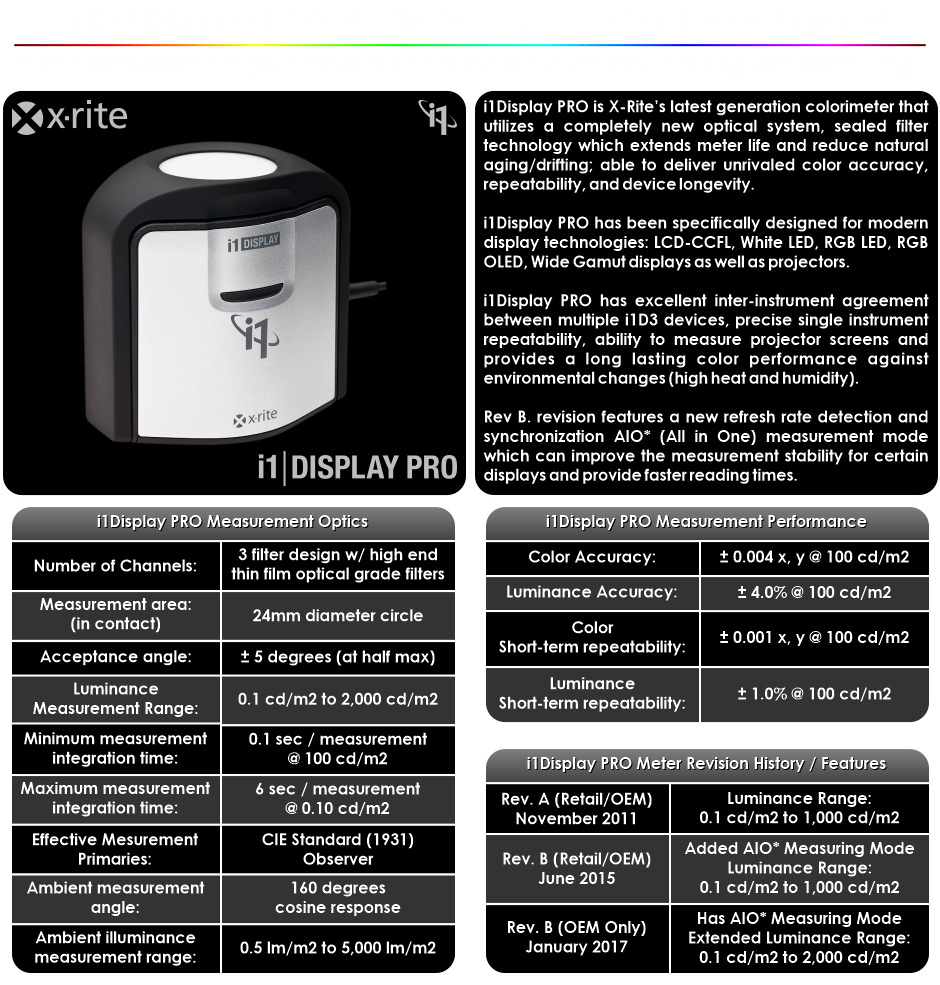

i1Display PRO is the ideal combination of color precision, speed and controls for the highest level of on-screen color accuracy.

The i1Display PRO is the ultimate choice for discerning photographers, designers, colorists, home cinema installers or any imaging professional looking for the highest on-screen color accuracy for displays, projectors, monitors, laptops, tablets and phones; it provides to serious Color Perfectionists with the perfect balance between speed, options and controls for unrivaled color precision.

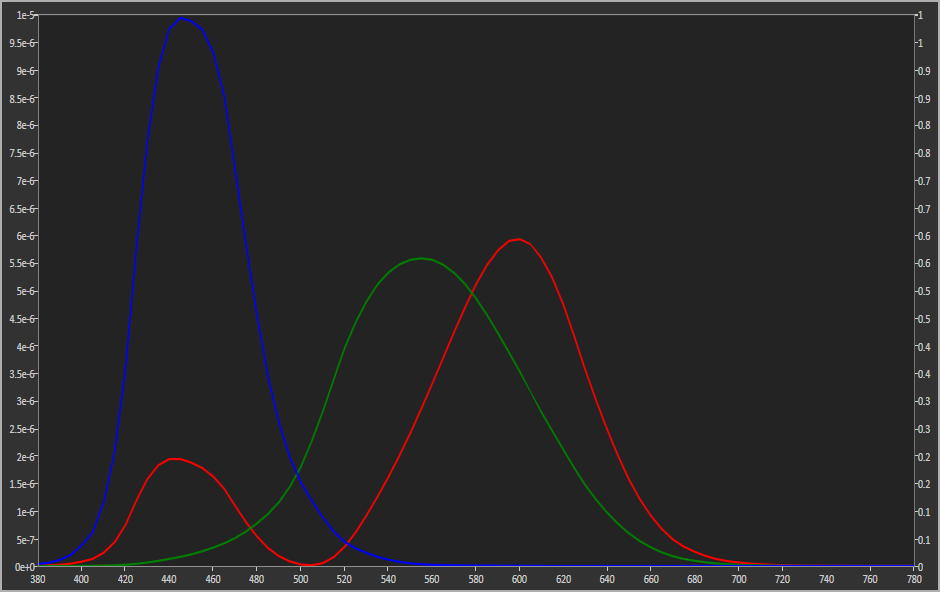

Technologically advanced i1Display PRO colorimeter for displays and projectors features an advanced and high-end optical system that provide a near perfect match to the color perception of the human visual system, delivering superior color measurement results.

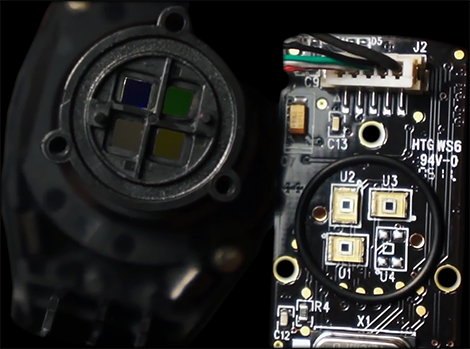

i1Display PRO is X-Rite’s latest generation colorimeter that utilizes a completely new optical system using 3 long-lasting dichroic thin-film optical grade glass filters technology to precisely shape the sensor spectral sensitivities. The result is excellent color matching function response.

The sealed filter technology using a rubber O-ring creates a seal during assembly between the optical mixing chamber with filters and the PCB with sensors, to extend the instrument’s life.

This design can reduce natural aging/drifting while the filter performance is robust against environmental changes of heat and humidity levels.

i1Display PRO has been specifically designed for modern display technologies: LCD-CCFL, White LED, RGB LED, RG Phosphor/GB-LED, RGB OLED, Wide Gamut displays as well as projectors.

i1Display PRO has excellent inter-instrument agreement between multiple i1 Display PRO devices with high degree of manufacturing consistency from batch to batch and precise single instrument repeatability.

i1Display PRO uses a new spectrally based calibration architecture for each available display type selection.

i1Display PRO is coming with spectral corrections for the following types: Generic CMF, CCFL-LCD, Wide Gamut CCFL-LCD, White LED, Wide Gamut RGB LED, OLED, Plasma, RG Phosphor (GB-LED), Projectors (DLP or LCD) with Ultra High Pressure (UHP) lamps. For each of these display types selection a spectral characterization at 1 nm internals using a Konica-Minolta CS-1000 spectroradiometer and each meter unique spectral sensitivities data measured during the manufacturing process and these data are used for the calculation of each display type spectral correction.

This spectral calibration architecture makes the i1Display PRO fully field upgradeable to support future display technologies.

These available spectral characterization options are stored inside X-Rite's SDK (Software Development Kit) files using X-Rite’s EDR (Emissive Display Reference) file format. New display technologies can be added with a newer release of X-Rite's SDK to software developers which can include the new display type selections to their future software releases.

i1Display PRO blazing fast measurement speed in an intuitive all-in-one design also adopted by leading display manufacturers as preferred color management device.

X-Rite i1Display PRO OEM Rev.B colorimeters (not the Retail); manufactured from January 2017 (or later); they are coming with an extended dynamic range hardware upgrade which X-Rite certifies that can measure up to 2000 nits.

According to X-Rite, all earlier (2016 or older) manufactured OEM meters or any revision of Retail meters (including 2017/2018/2019/2020 manufactured) had certified up to 1000 nits.

i1Display PRO features an ergonomic all-in-one design combines three important functions:

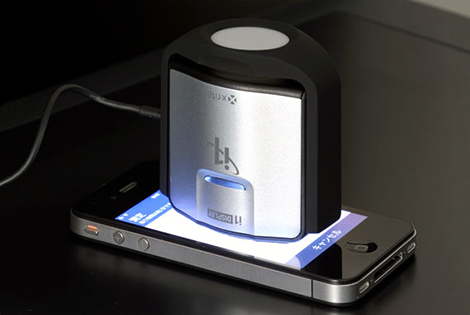

i1Display PRO has 24mm (diameter circle) measurement area in contact mode, ideal FOV (Field Of View) to evaluate the performance of any mobile or table screen.

You can connect the i1Display PRO to a computer on the same wireless network as your mobile device and launch the LightSpace Connect or SpectraCal MobileForge pattern generator (iOS or Android) app from your mobile/tablet.

LightSpace or CalMAN installed to that computer will control and accurately generate test patterns on your mobile device.

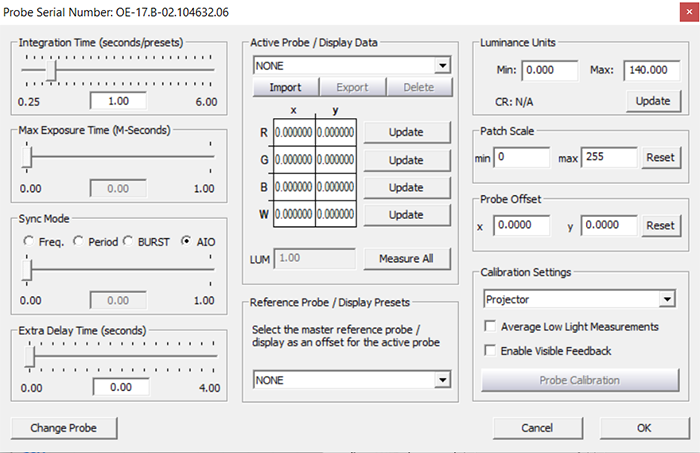

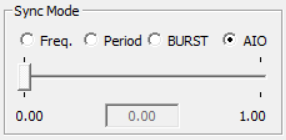

LightSpace CMS calibration software users have the capability to select the i1Display PRO's sync mode to best match their display/projector refresh/sync operation to provide better repeatability and faster measuring times.

The i1Display PRO sync modes for LightSpace CMS users are available to the 'Sync Mode' area of the LightSpace options window accessed via the Calibration Interface or Display Characterisation.

Using i1Display PRO (Rev.A), only Frequency (named as CRT at earlier LightSpace version), Period (named as LCD at earlier LightSpace version) and BURST modes are available, with BURST being suitable for displays that 'flicker', such as Plasmas and OLEDs with PWM (Pulse Width Modulation) type operation.

Using i1Display PRO (Rev.B) you have additionally the selection for AIO (All In One) mode which is a better option for most display types, especially PWM type displays. AIO (All In One) mode is a combination of Frequency & Period modes.

X-Rite i1Display PRO meter sync modes explained below:

As with any set of 'rules', in the real world nothing is written in stone. Measuring displays that use PWM, or other frequency/flicker based technologies, there is potential for the alternative modes Frequency/Period/BURST modes to provide enhanced precision in low-light levels, if the integration time is set to an extended enough duration.

Some LCD displays with excessive flickering will profile better with the BURST mode. There are no fixed rules - but BURST or AIO modes can often fix issues with Frequency (CRT) or Perion (LCD) modes.

Note that when the i1Display PRO attempts to measure levels below its minimum capability it may return measurement data that is 'generic', depending on the Sync mode selected. This tends to be more prevalent in Frequency (CRT) mode.

With the addition of Intelligent Integration, for many display types the use of Frequency (CRT) Mode may prove to provide the best possible measurements, as the integration time will be extended below the set Nits level, overcoming the inherent limitation with Frequency Mode when used without Intelligent Integration. But be aware Frequency mode (CRT) is NOT suitable for all display types - OLEDs for example.

Note that enabling Intelligent Integration is not recommended for Rev.A i1Display PRO users.

X-Rite's i1Display PRO called as i1D3, EODIS3 (names taken from its part number), i1Display 3 or i1Display III a lot of times at various calibration forum threads.

i1Display PRO can be found in 3 versions (Retail/OEM/Custom Branded OEM) and 3 revisions (Rev.A/Rev.B/Rev.B 2017/2018/2019/2020 manufactured):

Available at on-line stores (amazon, ebay, bhphotovideo, adorama etc.) or physical stores.

Only Retail version is working with X-Rite's i1Profiler software. i1Profiler can create VCGT (Video Card Gamma Table) LUT's / ICC profiles for unlimited number of monitors for PC/Mac OS systems.

Retail version is supported from the following calibration software solutions: CalMAN, ChromaPure, HCFR, DisplayCAL, ArgyllCMS, ArgyllPRO ColorMeter, Eizo ColorNavigator, Eizo ColorNavigator NX, EIZO ColorNavigator 7 (ColorEdge CG/CX Series; ColorEdge CG3145 is not supported), NEC SpectraViewII, BasICColor Display, LG True Color Pro, BenQ Palette Master Element, ViewSonic Colorbration, Fuji IS-mini Software, WOWOW Entertainment WonderLookPro, ATOMOS Calibration Software, BabelColor CT&A (Color Translator & Analyzer), BabelColor PatchTool and X-Rite ColorTRUE.

Officially it’s not supported by LightSpace; but we can make it work unofficially; contact us for more info.

There no meter serial or other info/marking outside of the Retail meter package to be able to identify the meter's revision. The instrument serial number is located on the sticker on the permanently attached counter weight. If it’s very old stock then it will be Rev.A; if it’s newer stock then it will be Rev.B or Rev.B 2017/2018/2019/2020 manufactured.

All Retail meters (Rev.A/Rev.B/Rev.B 2017/2018/2019/2020 manufactured) are certified from X-Rite to have luminance range from 0.1 to 1000 nits.

According to X-Rite, Rev. B 2017/2018/2019/2020 Retail manufactured meters are different build from Rev.B 2017/2018/2019/2020 manufactured OEM meters which has certified for extended dynamic range from 0.1 to 2000 nits.

Being certified to a specific nits level doesn't mean that the any revision of i1Display PRO will stop reading above that, just they are not certified to be accurate beyond its official certified luminance range capability.

All Retail Rev.B meters have updated hardware/firmware to support X-Rite’s new refresh rate detection and synchronization AIO* (All In One) measurement mode which can improve the measurement stability for certain displays and provide faster reading times.

AIO measurement mode can be used only from LightSpace (unofficially Retail meter can work with LightSpace; contact us for more info) or ChromaPure users only because these 2 calibration software solutions are using the official X-Rite SDK (Software Development Kit) to operate the meter.

CalMAN, HCFR, DisplayCAL ArgyllCMS and ArgyllPRO ColorMeter are operating the Retail meter with custom written code via alternative meter modes with adaptive integration times; they are not using X-Rite's SDK or AIO measuring mode.

Available at on-line stores from X-Rite OEM partners only.

OEM version will not work with X-Rite's i1Profiler.

OEM version is supported from the following calibration software solutions: LightSpace, CalMAN, ChromaPure, HCFR, DisplayCAL, ArgyllCMS, ArgyllPRO ColorMeter, Eizo ColorNavigator, Eizo ColorNavigator NX, EIZO ColorNavigator 7 (ColorEdge CG/CX Series; ColorEdge CG3145 is not supported), NEC SpectraViewII, BasICColor Display, LG True Color Pro, Fuji IS-mini Software, WOWOW Entertainment WonderLookPro, JVC Monitor Calibration Software, BabelColor CT&A (Color Translator & Analyzer) and BabelColor PatchTool.

OEM meter can be found in all revisions (Rev.A, Rev.B or Rev.B 2017/2018/2019/2020 manufactured).

All OEM Rev.B meters have updated hardware/firmware to support X-Rite’s new refresh rate detection and synchronization AIO* (All In One) measurement mode which can improve the measurement stability for certain displays and provide faster reading times.

AIO measurement mode can be used only from LightSpace or ChromaPure users because these 2 software solutions are using the official X-Rite SDK (Software Development Kit) to operate the meter.

CalMAN, HCFR, DisplayCAL ArgyllCMS and ArgyllPRO ColorMeter are operating the OEM meter with custom written code via alternative meter modes with adaptive integration times; they are not using X-Rite's SDK or AIO measuring mode.

X-Rite (silently) without any public statement/press release; starting from January 2017; they manufacturing only OEM Rev.B version of i1Display PRO with a hardware upgrade to extended its luminance range capability from 0.1 to 2000 nits.

This new certified extended luminance range upgrade provides the capability for i1Display PRO OEM Rev.B (2017/2018/2019/2020 manufactured) to measure and calibrate for HDR-10 or Dolby Vision modes of high-brightness LED-LCD/QLED HDR display models from Samsung/Sony which were capable up to 2000 nits or forthcoming OLED models which will have beyond 1000 nits output capability.

According to X-Rite, only the Rev.B OEM version of the meter (not the Retail) manufactured from January 2017 or later is certified to measure up to 2000 nits.

Being certified to a specific nits level doesn't mean that the any revision of i1Display PRO will stop reading above that, just they are not certified to be accurate beyond its official certified luminance range capability.

Available on-line from X-Rite Custom OEM partners only. Some custom branded meters are available to physical stores or other on-line stores.

Custom branded version is intended for OEMs that do not want to share their proprietary device with other 3rd party software developers. The decision to use these proprietary devices is made solely by the OEM and not X-Rite. This device will have custom side panels with the OEM’s name. In addition, the part number will include either “OEM” or another OEM defined set of characters.

This device will work ONLY with this OEM software and will not work with X-Rite's i1Profiler software.

X-Rite is shipping two kinds of OEM versions to third-party vendors. An open OEM-version which can be used in all apps which are supporting the retail/open OEM version of the instrument. And there is a second (closed) OEM version which supports only the app of the 3rd-party vendor and cannot be used by other 3rd-party apps.

For example; SpectraCAL C6 or C6-HDR is a Custom OEM branded i1Display Pro (Rev.A or Rev.B) while SpectraCAL C6-HDR2000 is a Custom OEM branded i1Display Pro (Rev.B 2017/2018/2019/2020 manufactured).

Unofficially; the SpectraCAL C6/C6-HDR meters can work with HCFR, DisplayCAL, ArgyllCMS and LightSpace (about LightSpace; contact us for more info).

Other examples of Branded OEM versions are: HP DreamColor, NEC SpectraSensor PRO, Quato Silver Haze 3, Wacom Color Manager, Toshiba Picture Analyser 1 (TPA1) and basICColor display SQUID 3. Unofficially all these branded OEM meters can work with LightSpace also; contact us for more info.

If you have bought your i1Display PRO OEM meter already; to identify the revision or the year/month of manufacture then you can look the meter's serial number which is located on the sticker on the permanently attached counter weight.

The

(OE = OEM version, yy = short year manufactured, r-02 = hardware revision (A or B) - firmware version (02), xxxxxx = incremental number, mm = month manufactured)

The

(i1 = Retail version, yy = short year manufactured, r-02 = hardware revision (A or B) - firmware version (02), xxxxxx = incremental number, mm = month manufactured)

If your OEM meter has ''yy = 17'' means that its the OEM Rev.B 2017 manufactured and certified for extended dynamic range up to 2000 nits; capable for HDR10/Dolby Vision calibration of current high-brightness LCD-LED/QLED models available in the consumer market.

If your OEM or Retail meter has hardware revision number ''B-02'' and ''yy = 16'' or earlier then its a Rev.B certified up to 1000 nits.

Any OEM or Retail meter with hardware revision number ''A-02'' then its a Rev.A certified up to 1000 nits also.

(SP = SpectraCAL version, yy = short year manufactured, r-02 = hardware revision (A or B) - firmware version (02), xxxxxx = incremental number, mm = month manufactured)

The current batch (July 2017) of SpectraCAL C6-HDR2000 branded OEM meters has hardware revision number ''B-02'', ''yy = 17'' and ''mm = 06'' or later; same revision/yy/mm as the batch of meters X-Rite is shipping from their warehouse for i1Display PRO OEM version, both meters are certified up to 2000 nits.

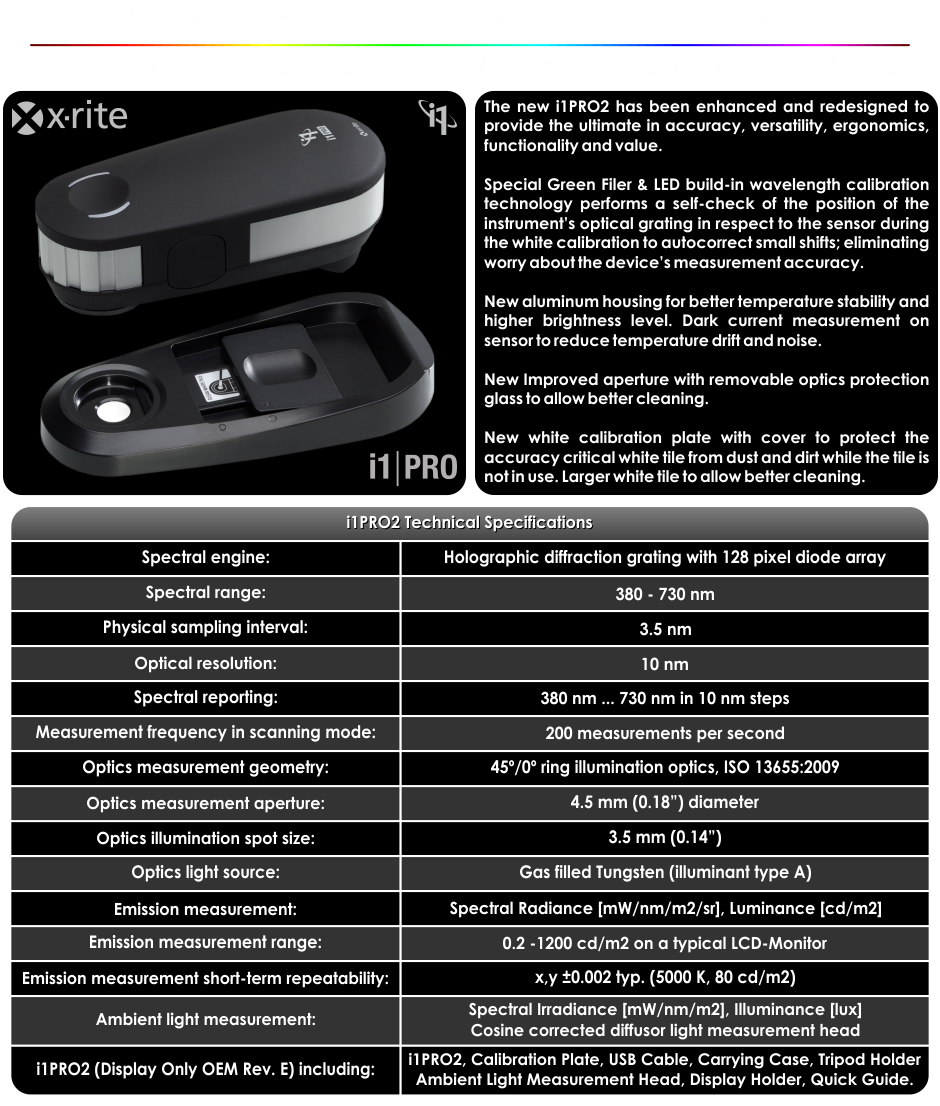

Built upon the success of X-Rite’s i1PRO spectrophotometer as the de-facto industry standard for more than a decade, i1PRO2 features the next generation of X-Rite's industry-leading technology delivering increased accuracy, ease of use and an expanded professional-level feature set.

i1PRO2 is the new standard of perfection for Color Perfectionists looking for an affordable, professional-level spectral color measurement solution offering display and projector color measurements designed for an imaging professional’s unique needs.

The X-Rite i1PRO2 is a true spectrophotometer, featuring greater accuracy than tri-stimulus colorimeters which are based on color filters.

A new innovative Swiss-engineered design makes the i1PRO2 much more affordable than previous generations of spectrophotometers.

X-Rite's i1PRO2 better temperature stability and higher brightness levels improve emissive measurements, resulting in the best possible calibration and profiling of monitors and projectors.

Adaptive integration allows best possible performance in display profiling – avoid drift due to temperature change of the device during longer display measurement cycles.

Maintaining and protecting the device (and investment) is easier than ever with the improved aperture and the new white calibration plate.

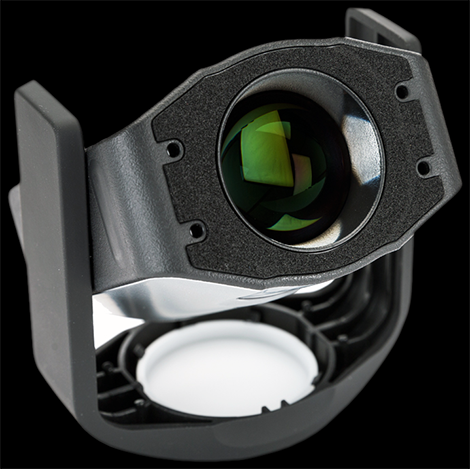

The i1PRO2 can be used for contact measurements and includes a completely re-designed hardware for holding the meter against the region of the display being measured for accurate monitor profiling.

To prepare the i1PRO2 device for a display measurement you need to mount the i1PRO2 device on the display holder.

You can adjust the length of the counter weight of the display holder for the size of your screen. The counter weight is equipped with hook-and-loop fasteners on both ends which allow you to shorten and lengthen the display holder to the correct length.

Mount the i1PRO2 measurement device on the display holder by inserting the mounting connector on the display holder in the mounting interface at the rear of the i1Pro device. Make sure that the nose of the i1PRO2 device seats firmly in the display holder.

i1PRO2 PRO has 4.5mm (diameter circle) measurement area in contact mode, ideal FOV (Field Of View) to evaluate the performance of any mobile or table screen.

You can connect the i1PRO2 to a computer on the same wireless network as your mobile device and launch the LightSpace Connect or SpectraCal MobileForge pattern generator (iOS or Android) app from your mobile/tablet.

LightSpace or CalMAN installed to that computer will control and accurately generate test patterns on your mobile device.

For non-contact measurements its including a beamer holder accessory for hands-free display/projector profiling.

To prepare the i1PRO2 device for projector or non-contact display measurements you need to mount the tripod holder on the tripod holder base plate, or on a tripod with a standard 1/4” screw you supply.

i1PRO2 includes an ambient light measurement head which can be attached to be able to measure the ambient light of an environment or take illuminance measurements directly from a front projector's lens. The ambient light measuring head is stored in the bottom of the tripod holder.

If you own multiple devices make sure that the serial number on the ambient light measuring head matches the serial number of your i1PRO2 device. The ambient light measuring head can also be used in conjunction with the tripod holder.

The i1PRO2 can return CIE Lxy data for photometry measurements and can also return raw spectral data between 380 nm and 730 nm at 10 nm intervals for radiometry applications.

i1PRO2 is certified to measure up to 1200 nits capable HDR displays with high luminance output technology like LCD-LED/QLED/OLED. All previous revisions of i1PRO1 were certified up to 300 nits luminance range only.

If you have a display which can output higher luminance level beyond certified luminance capabilities if i1PRO2; during meter profiling procedure of your colorimeter for HDR calibration; you can use 75% stimulus level patterns during meter profiling because they will have about 980 nits output; luminance levels inside the i1PRO2's certified luminance range capabilities, not use 100% stimulus level patches for this case.

After the meter profiling procedure, you can continue using your i1Display PRO OEM (2017/2018/2019/2020 manufactured) colorimeter which is certified for 2000 nits or other high-luminance capable colorimeter like: basICColor DISCUS (2500 nits), Colorimetry Research CR-100 (5140 nits) or Klein Instruments K-10A (10000 nits).

Being certified to a specific nits level doesn't mean that the any revision of i1PRO1/2 will stop reading above that, just they are not certified to be accurate beyond its official certified luminance range capability.

i1PRO2 (Rev.E) has higher scanning measurement speed (200Hz) from the original first generation of i1PRO1 (Rev.A) which had 100Hz, resulting in higher profile accuracy and faster measurements.

Built-in wavelength calibration technology allows for self-diagnosis of the position of the optical grating in respect to the sensor during white calibration, eliminating worry about your device’s measurement accuracy.

i1PRO2 has 128 sensors binned into 41 10nm increments. The mechanical alignment feature will make sure the 41 increments are accurately aligned with the 128 sensors.

Special Green Filer and LED Performs instrument self-check on every Calibration.

i1PRO2 has a reference spectrum of the (green) wavelength LED stored in its firmware, during the wavelength calibration the driver computes a wavelength offset in the sensor to wavelength interpolation tables to ensure that the measured spectrum of the green LED matches that of the firmware reference. Too large a shift and it will error out. Zero shift and nothing has moved in the hardware.

Instrument can automatically self-diagnose and correct for small shifts as well as identify recalibration needs.

Damaged instruments can be identified for required repair.

i1PRO2 sensors sensitivity was changed so it'll be a little bit better at low light compared to earlier revisions of i1PRO1.

Improved aperture for increased accuracy and reliability features a removable optics aperture protection glass to allow better protection and easy for the user to clean, minimizing dust and dirt interference.

You can use isopropyl alcohol on a soft clean cloth to clean the protection glass and the inside of the limiting aperture.

New white calibration plate with cover to protect the accuracy critical white tile from dust and dirt while the tile is not in use.

In the center of the calibration plate is a slider to protect the white calibration tile. Open this protective slider until it clicks into place to access the white reference ceramic tile on this calibration plate.

Dark current measurement on sensor will reduce temperature drift and noise.

Larger white tile area ensures measurement accuracy and makes better cleaning very easy. A clean white reference ceramic tile is essential for providing accuracy of your measurements.

The protection cover should always be closed when the white reference ceramic tile is not in use. If necessary you can clean the white reference ceramic tile with isopropyl alcohol and a soft clean cloth.

The new aluminum frame works as heat sink providing best possible performance in display and projector profiling and adds stable connection between instrument and accessories.

The temperature drift compensation reduces noise to attain better accuracy for measurements on dark patches.

i1PRO2 spectrophotometer is equipped with two new status LED indicators on its top housing which can guides the users through the measurement process and provides feedback on device status, improving the user experience and saving time.

The device status indicators provide the following feedback on the current status of the device:

Off - The device is either not connected to your computer, the software is not running, or the latest software to control the device is not installed on your computer. In the third case, the device can still be used in compatibility mode with software Supporting older revisions of the i1PRO1 device.

Solid White - The device is connected but needs calibration.

Pulsating White - The device is connected and ready for measurement.

Solid Red - The calibration of the device failed due to a hardware problem (see troubleshooting section of X-Rite's i1PRO2 on-line PDF manual for further information).

Pulsating Green - Measurement successful.

Pulsating Red - Measurement unsuccessful.

Pulsating Blue - Indicate next measurement direction.

To avoid interference of the device status indicators with the measurement process, the device status indicators are switched off during measurement.

The backward compatibility mode allows using your i1PRO2 device in with any software developed for the original first generation i1PRO1 spectrophotometer, offering same functions you previously had access to.

The i1PRO2 is a USB 1.1 high power device (5V, 500mA) that draws a substantial amount of current from a USB port. The i1PRO2 draws more power when it turns its two light sources on (Tungsten light bulb and UV LED) for reflective measurements. When its measuring emissive sources (displays/projector screens) these light sources are not used, except during its white ceramic tile calibration.

Unpowered USB hubs and some USB ports do not supply enough current, and some USB extension cables may limit the current.

The power from the USB port is monitored to ensure that adequate power is delivered from computer USB port to the i1PRO2 device, so you can be confident your device is functioning properly.

Using earlier revisions of i1PRO1 (Rev.A/B/C) while making emission measurements on an LCD display, it was noticed that different Luminance and Correlated Color Temperature (CCT) values were obtained, depending on the instrument’s position on the display.

Luminance variations by as much as 10% were measured for the same display area when rotating the spectrophotometer by 90-degree.

This problem has essentially disappeared using i1PRO1 Rev. D or i1PRO2 Rev. E; it was a problem related to the polarization of the light emitted from the display.

In an LCD display, the intensity of each pixel is controlled by rotating the light's polarization state between crossed polarizers, and the light coming out is linearly polarized (often at a 45-degree angle).

The display light is not seen differently by the human eye whether it is polarized or not, since we only perceive the light intensity; however, polarization can affect an instrument reading.

i1PRO2 OEM Rev.E (Display Only) version is supported from all the following calibration software solutions: LightSpace, CalMAN, ChromaPure, HCFR, DisplayCAL, ArgyllCMS, ArgyllPRO ColorMeter, Eizo ColorNavigator, Eizo ColorNavigator NX, EIZO ColorNavigator 7 (ColorEdge CG/CX Series), NEC SpectraViewII, BasICColor Display, LG True Color Pro, BenQ Palette Master Element, Sony Monitor Auto White Adjustment, Fuji IS-mini Software, WOWOW Entertainment WonderLookPro, BabelColor CT&A (Color Translator & Analyzer), BabelColor PatchTool, SpectraShop and Panasonic 4LH310 LCD Monitor Utility Software (Legacy Mode)

OEM Rev. E Display Only version of X-Rite's i1PRO2 spectrophotometer will not work with X-Rite's i1Profiler. The package will not include the following accessories which are useless for display/projector measurements: positioning target, scanning ruler, backup board.

i1PRO2 (Display Only OEM Rev.E) soft carrying case is including: i1PRO2, Calibration Plate, NIST traceable Calibration Certification, USB Cable, Beamer Tripod Holder, Ambient Light Measurement Head, Display Holder, Quick User Guide.

The i1PRO2 device is sensitive to mechanical shocks. To avoid damage during transport the i1PPRO2 must be always shipped in its original carrying case.

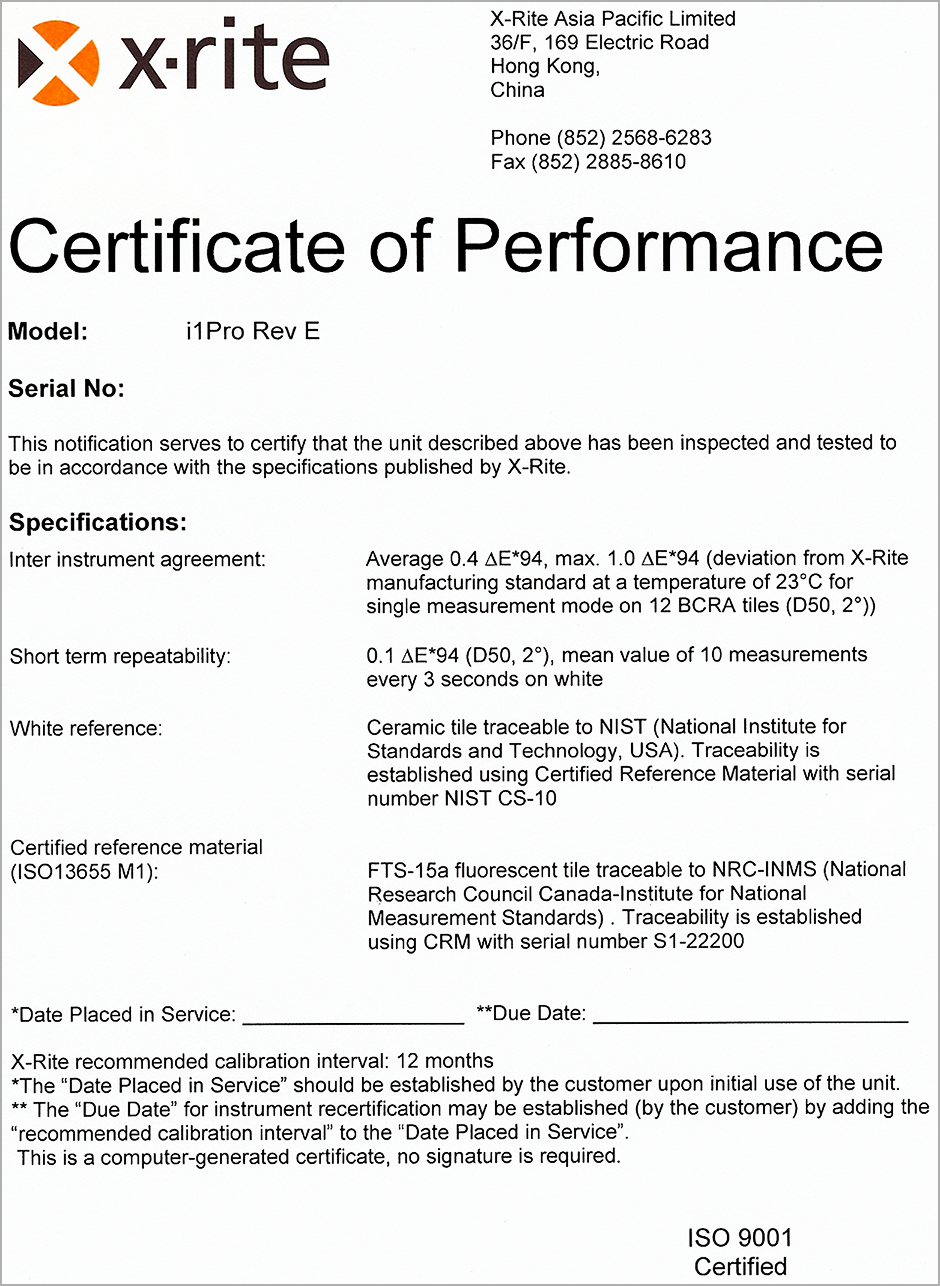

X-Rite's i1PRO2 is coming with a certification of performance from X-Rite's Calibration Labs (ISO 17025 accredited laboratory) traceable to NIST (National Institute of Standards and Technology) measurement standards.

X-Rite is using a Konica-Minolta CS-1000 spectroradiometer as a reference and an industry standard sample set of 12 BCRA (British Ceramic Research Association) ceramic tiles and a FTS-15a fluorescent tile also as reference materials to certify and guarantee the inter-instrument agreement and short-term repeatability of each certified instrument individually.

The normal certification interval X-Rite recommends is 12 months. New instruments still get 18 months from the date of manufacture to allow for delays in the distribution channel.

X-Rite's Calibration Laboratories use ISO/IEC 17025 which is the main ISO to implement a quality system aimed at improving the ability to consistently produce valid results of testing and calibration laboratories. Technical requirements include factors which determines the correctness and reliability of the tests and calibrations performed in a ISO 17025 accredited laboratory.

ISO 17025 specifies the general requirements for the competence to carry out tests and/or calibrations and applies directly to those organizations that produce testing and calibration results. In most major countries, ISO/IEC 17025 is the standard for which most labs must hold accreditation in order to be deemed technically competent. In many cases, suppliers and regulatory authorities will not accept test or calibration results from a lab that is not accredited.

One of the requirements of ISO 17025 is that the calibration interval be set by the customer not the manufacturer or the calibration lab. X-Rite provides a general recommendation of annual certification, but each customer has to decide whether his conditions are average or not.

Customers must consider the potential consequences and costs of incorrect measurements. If a non-conforming instrument is easily detected in the workflow or the cost of incorrect measurements is minimal, a customer may rightfully decide to not send in the instrument until he gets an error message.

Obviously, nobody can guarantee that the instrument will perform perfectly within any given certification period. Conscientious customers will have regular checks in place that verify the proper performance of their instrument.

The calibration and recertification services that X-Rite's authorized repair centers provide guarantee that the instrument is in compliance with the manufacturer's current specifications. These certifications renew the instrument's traceability to national standards. They also minimize future problems by analyzing components and recommending parts replacement where necessary.

As far as the accuracy and repeatability specifications are concerned, X-Rite do not expect an instrument to be out of specification after 12 or even 18 months. But, obviously, due to the varied environments and intensity of usage, there is a potential that some instruments may be out of our specifications as their lamps or electronics may deteriorate.

A Return Material Authorization (RMA) is required from X-Rite in order for the customer to return a unit for recertification.

There two types of calibration devices that can be used for display calibration measurements:

A colorimeter makes use of filters to measure the intensity of red, green and blue. The filters reduce a broad range of light wavelengths into a few measurement values. Therefore, the accuracy and quality of these instruments depend a lot on the filters used - how durable they are over time, what colors they are specifically created to measure and how accurately their coloration matches the standard observer curves.

All colorimeters will eventually suffer from the filter deterioration over time, although some colorimeters suffer from the effects of filter deterioration at a much slower rate as a result of their sealed filter enclosure design.

Various factors can influence the calibration of a device, such as prolonged exposure to high humidity, prolonged exposure to sun light radiation, heat and natural variances.

There colorimeters which have an internal EPROM that needs yearly calibration to adjust for changes of the internal color filters. This EPROM in the colorimeter can store different calibration tables trying to match better different display technology spectral power distribution (SPD) color matching curves.

Filter-based colorimeters, although not inherently as accurate on all displays as spectrophotometers/spectroradiometers, but they have better low light sensitivity, are more accurate at measuring the display black levels and can measure fairly quickly at all light levels. Their fast measurements make colorimeters very convenient for performing classic display calibrations using internal display calibration controls adjustments or display characterization using external LUT holder devices using 3D LUT (Look-Up-Table) which will require some thousands color point measurements.

Τristimulus colorimeter has features such as comparatively low price, compact size, speed, high sensitivity, superior mobility and simple operation; so all these features makes it a first choice as stand-alone instrument for a display calibration measurements.

Meter profiling using a spectrophotometer/spectroradiometer as a reference can be a process for improving the accuracy of a filter-based colorimeter.

Meter profiling is using the Four-Color Matrix Method which is a process for improving the accuracy of a filter-based colorimeter, for a specific display. Profiling creates a calibration profile for the colorimeter based on the unique spectral characteristics measurement data from a reference spectrophotometer.

This meter profiling procedure transfers the color accuracy of the spectrophotomer/spectroradiometer to the colorimeter readings; so color accuracy is added to the high-speed, low light sensitivity of the colorimeter readings which will perform later all the measurements; as a stand-alone meter; the whole calibration process.

This is why having both a spectrophotometer/spectroradiometer and a colorimeter its the best choice to achieve the most accurate results when you want to measure any display/projector technology device.

The spectrophotometers/spectroradiometers are designed to measure light energy at various frequencies across the entire spectrum of visible light, they are highly accurate and display agnostic and this allowing them to be used with all current and future display technologies.

A spectrophotometer/spectroradiometer breaks light up into a spectrum using a color grating. Then an array of sensors reads each section of the spectrum to produce the spectral data.

Their measurement returns data from 380nm (nanometers) to 780nm; which is the visible light spectrum; or broader. Basically, it measures many bands of light at once. These different bands of spectral data are brought together to identify individual colors.

Measuring across bands of light in this manner can very accurately describe the quality of light that is output from a display, but does have the drawback of often taking much longer to take readings at lower light levels as each sensor is collecting only a small fraction of the available light. It also requires dark calibration offsets to ensure accuracy; this can be an automated shutter mechanism in more sophisticated models or a regular manual dark calibration in consumer models.

Because a spectrophotometer/spectroradiometer gathers such complete color information, that information can be translated into colorimetric data with just a few calculations.

Because all values are calculated from the absolute spectral power distribution (SPD), errors arising from filter mismatch common to filter colorimeters are eliminated making highly accurate measurements of narrow band sources or other “spiky” sources.

In short, a spectrophotometer/spectroradiometer is the most accurate, useful, and flexible instrument available.

Colorimeters are tristimulus (three-filtered photodiodes) devices that make use of red, green, and blue filters to emulate the response of the human eye to light and color.

In the human eye, there are sensors called 'rods' and 'cones' that actually create the nerve impulses in response to light. It has three types of color sensors known as red, green and blue cone cells which work together through the brain to give the perception of all colors. A fourth type of sensor, rods, provides humans with their night vision.

What we perceive as white light is actually all these primaries combined in a defined proportion of red, green and blue. Our concept of white is actually relative – the human eye adapts to its environments and perceives as white the maximum intensity to which it is currently sensitized. This is why white can be redefined by various standards-setting bodies based upon their needs. The implication of this is that what we perceive as black is actually the result of no light being produced, and the color gray actually contains the same mix of red, green and blue – just at a lower intensity level than the current reference white.

The human eye exhibits a characteristic variation in spectral response over the 380-780nm band (Visible Spectrum), referred to as the photopic response. Photometry is the science of measuring light scaled to how the human eye would see it. The eye’s photopic response is the reason why we see one unit of green light as being much brighter than one unit of blue or red light. The eye is most sensitive to yellow-green light (specifically 555nm); a color which corresponds to the peak wavelength of sunlight that reaches the earth’s surface.

While the wavelengths present do control what color we see, rods are sensitive to varying degrees for each wavelength. As one might expect, there is one or more peaks where the individual rod is most sensitive, and then its sensitivity falls off rapidly for longer and shorter wavelengths. As a result, what we see as one “color” is actually an amalgamation of wavelengths. For example; we are least sensitive to blue intensity, but are more sensitive to color deviations in blue than in either green or red.

The sensitivity of each individual‘s eyes is slightly different; even for people considered to have 'normal' color vision, there may be some bias toward red or blue. Also, a person‘s eyesight generally changes with age. Because of these factors, colors will appear differently to different observers.

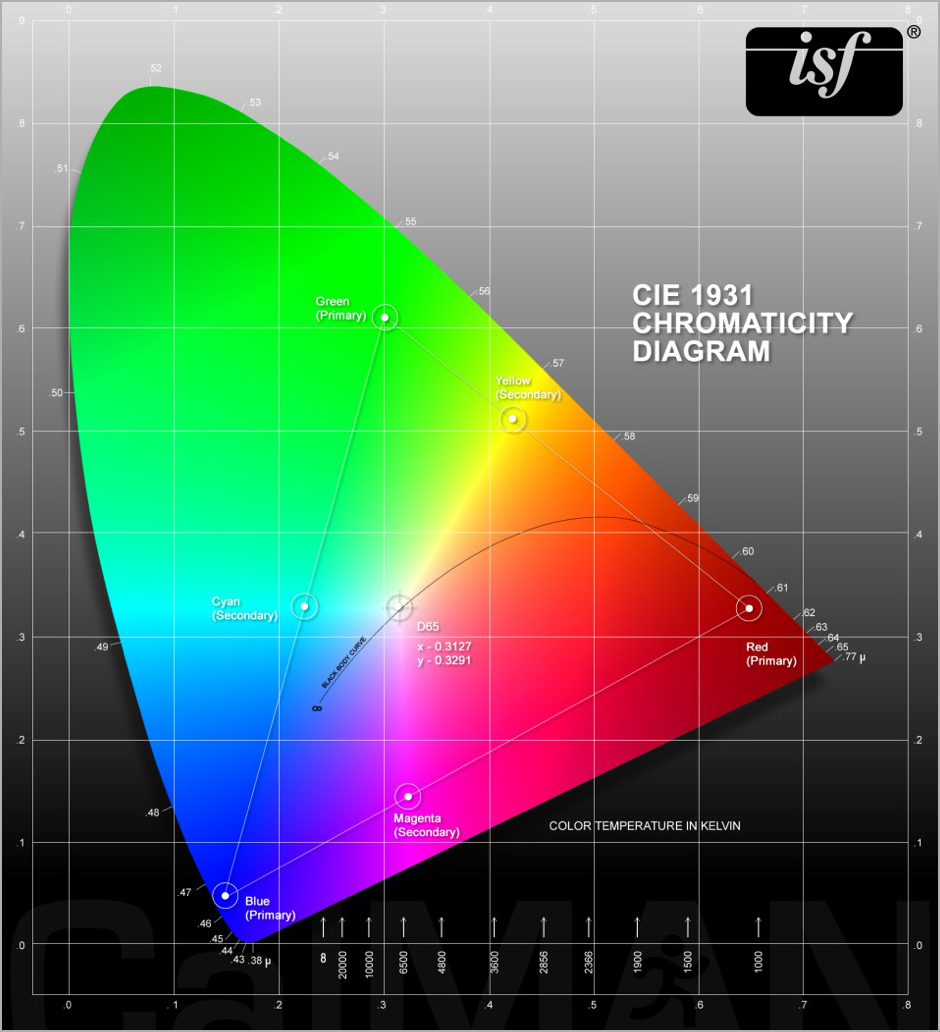

In an attempt to accurately model human color vision using three filters, in the year 1931 the CIE (Commission Internationale de l'Eclairage, or International Commission on Illumination) defined the standard observer color matching functions (CIE1931 CMF) which was based on the average human response (1000 testing persons) to wavelengths of light. In short, the standard observer represents how an average person sees color across the visible spectrum.

The color matching functions are the tristimulus values of the equal-energy spectrum as a function of wavelength. These functions are intended to correspond to the sensitivity of the human eye (normal observer).

The CIE conducted color-matching experiments on a number of subjects, then they used the collective results to create “color-matching functions” and a “universal color space” that represents the average human’s range of visible colors.

The color matching functions are the values of each light primary; red, green, and blue; that must be present in order for the average human visual system to perceive all the colors of the visible spectrum. The results of the matching are reported as three values: X, Y, and Z which were assigned to the three primaries.

'X' corresponds with the intensity of light perceived (spectral power distribution or SPD) by the 'red' cones, 'Y' corresponds with the intensity of light (SPD) perceived by the 'green' cones, and Z corresponds to the intensity of light (SPD) perceived by the 'blue' cones.

Once data is captured as XYZ tristimulus values, it is usually converted arithmetically into another color description system, such as CIE xyY as CIE constructed the xyY Chromaticity Diagram to define the visible spectrum.

The color sensitivity of the eye changes according to the angle of view (object size). The CIE originally defined the standard observer in 1931 using a 2-degree field of view, hence the name CIE1931 2-degree Standard Observer.

The CIE1931 2-degree standard observer CMF is the basis for practically all current professional video/display standards.

A tristimulus colorimeter uses filters to separate light out into color components, and then fits those to matching curves based on the human eye, to produce color values in one or another three-value color space (XYZ, xyY, etc.) based on what the human eye would see.

The goal of any tristimulus colorimeter is to measure a display with responses matching the three CIE color-matching functions. In order to do this the colorimeter typically employs some form of filter/detector combination.

Filtering detector response to match the CIE color-matching functions is difficult. In fact, most commercial tristimulus colorimeters, have significant detector/filter errors.

Measurement results can be reasonably accurate when the colors are broadband because colorimeters are typically calibrated against NIST (National Institute of Standards and Technology) traceable and spectrally broadband CIE Illuminant A source of light having a correlated color temperature (CCT) of 2856 K to represent typical, domestic, tungsten-filament lighting. Some colorimeters are being calibrated against a reference state-of-the-art grade one LCD monitor.

Because the three primary colors (red, green, blue) that comprise the color gamut of LCD, LED or OLED displays are usually other than broadband; deviations from the desired color-matching-function responsivities can occur that will result in significant errors in color and luminance measurements whenever the spectra of the colors are no longer broadband; when measuring the primary colors of a display, or any mix of them.

Due to imperfect spectral matching of the three channels to the color matching functions (CMF) measurement errors occur, which rise with increasing spectral difference between calibration source and test source.

For that reason, i1Display PRO is coming with additional (from default Generic CMF) spectral corrections for each display technology (CCFL, Wide Gamut CCFL, White LED, RGB LED, OLED, Plasma, RG Phosphor, Projection) because different display technology can have very different spectral power distributions; these additional tables helps to reduce the chromaticity/luminance errors.

i1Display PRO colorimeter initially designed mainly as the ideal tool for web-designer/photographer and post-production market; while it became very popular to the consumer TV/Projector market also; so the models of the displays used from X-Rite to measure and create each display technology spectral characterization correction (at 1 nm internals using a Konica-Minolta CS-1000 spectroradiometer) was selected from a list of popular displays from these markets.

For example, X-Rite used a Sony PVM-2541 RGB OLED Monitor to create the OLED spectral correction for i1Display PRO which can be useful when you will measure the Sony or FSI (Flanders Scientific Inc.) RGB OLED Broadcasting Monitors and not a consumer LG WRGB OLED or the following brands which are using LG's WRGB OLED panel also: Sony, Panasonic, FSI (XM650U), Toshiba, Loewe, Philips, Skyworth, Metz, Grundig, Vestel, Arçelik, HiSense and Bang & Olufsen.

X-Rite has added (August 2018 SDK) to the OLED EDR (Emissive Display Reference) file spectral data for 2 additional RGB OLED displays; for Lenovo ThinkPad X1 Yoga 2017 Gen 2 (LEN4140) Laptop and Samsung Galaxy S7 Smartphone.

For RG Phosphor (GB-LED) they used the Dell Ultrasharp U2413 (for GB-LED) and AU Optronics B156HW01 Monitors, not a popular Vizio RG Phosphor consumer display. GB-LED spectral correction is included inside the RG Phosphor selection.

For LCD-CCFL IPS (EIZO/HP LP2465), for Wide Gamut LCD-CCFL (NEC 241/271/PA271W), for Projection (Marantz/HP/Panasonic), for CCFL-LED IPS (Eizo/HP), for RGB-LED (HP/SOYO) and for White-LED IPS (LG/Samsung SyncMaster/AU Optronics B156HW01).

The only exception was for Plasma where they used a consumer Panasonic Plasma TV.

The displays are rapidly changing/improved very fast so a spectral power distribution (SPD) of one display can be significantly different from another, even under the same display technology. Even though the colorimeter has been precisely calibrated at its factory for a specific display type, the SPD of the display it was calibrated on may not precisely match the SPD of the display you are currently measuring.

Various brands and models of LCD's also use very different filters or light sources which can easily affect a colorimeter’s calibration; this is a problem with wide gamut LCD monitors which use a green filter quite different than the ones used in smaller gamut monitors.

A colorimeter with a matching display technology mode selected which is the same with the display technology panel you are measuring it will be more accurate than a colorimeter using its Generic CMF meter mode selected.

Meter profiling is a process for improving the accuracy of a filter-based colorimeter, for a specific display. Profiling creates a calibration profile for the colorimeter, for the display currently being measured, based on display measurement data from a reference spectrophotometer/spectroradiometer.

Reference spectrophotometers/spectroradiometers are very accurate when measuring light from different sources, even those with vastly different spectral power distributions (SPDs).

Spectrophotometer/Spectroradiometer measures the display light in separate wavelength bands; these bands are located at fixed intervals, generally 5 (at high-end spectroradiometer models) or 10 (at i1PRO2) nanometers (nm) apart, between 380 and 730 nm.

During a measurement, the optical incoming signal imaged onto the diffraction grating where it is broken up into its component wavelengths. The diffracted spectrum is then relayed to the detector, where each of the 128 (of i1PRO2) detectors is illuminated by a discrete band of the diffracted spectrum, then them signal is converted from analog to a digital signal using an A/D converter and its corrected for wavelength accuracy and intensity per wavelength by factors determined during the calibration of the instrument.

Once the spectral distribution is measured, all other photometric, radiometric and colorimetric values are mathematically calculated. Following a spectroradiometric measurement, the tristimulus values X, Y and Z are obtained by integrating the spectral data with the CIE color matching functions.

The calculated tristimulus values are then used to compute CIE chromaticity coordinates and correlated color temperature, which provides a complete description of the color of the source.

Because all values are calculated from the absolute spectral power distribution (SPD), errors arising from filter mismatch common to filter colorimeters are eliminated making highly accurate measurements of narrow band sources or other “spiky” sources possible.

However, spectrophotometers like i1PRO2 have poor light sensitivity and measure very slowly at low light levels and they are not so accurate also. The slow speed and reduced color accuracy of a spectrophotometer like i1PRO2 makes it inconvenient for performing multiple display calibration measurements or display characterization measurements (3D LUT) as stand-alone meter, but its the best choice for creating individual profile of each and every display for colorimeters; the spectrophotometer would be the 'reference' meter.

High-end spectroradiometers (5 nm) can be used as a stand-alone meter because they are capable to measure accurately low luminance levels (more CCD sensors, lower signal-to-noise ratio) but they will require much more time for a single measurement so it can be used for normal display calibration using display internal calibration controls only, not for 3D LUT display characterization which will require thousands color point measurements which will include a lot of low luminance level patch readings which will extend a lot the total required measurement time.

A spectrophotometer/spectroradiometer is the best choice as a primary reference calibration instrument to create colorimeter profiles as a reference meter.

The best choice to achieve the most color accurate results by measuring any display/projector technology will require to have both a spectrophotometer/spectroradiometer and a colorimeter.

Meter profiling is a process for improving the accuracy of a filter-based colorimeter, for a specific display. Profiling creates a calibration profile for the colorimeter, for the display currently being measured, based on display measurement data from a reference spectrophotometer/spectroradiometer.

When you profile a colorimeter, you measure the unique spectral characteristics of a display with a spectrophotometer/spectroradiometer and basically you transfer that accuracy to your colorimeter, for that display.

The process is known as the Four-Color Matrix Method (FCMM) for Correction of Tristimulus Colorimeter developed by Ohno and Hardis at NIST (National Institute of Standards and Technology).

The accuracy of this method has been studied further from NIST for spectral variations of displays including CRTs, LCDs, and OLED displays and it works well.

The procedure starts using a reference spectrophotometer/spectroradiometer which measures 4 color patches, the primary colors (red, green, blue) and white of a certain display technology and then using a colorimeter it will measure these 4 color patches (W,R,G,B) of the same display also.

From these 8 in total measurements (4 per each meter), a 3x3 XYZ matrix correction table will be created and it will transform the colorimeter results as close as possible into the results obtained by the spectrophotometer/spectroradiometer used. The correction matrix is not a simple x,y subtraction/offset, which would result in unpredictable and invalid results.

That generated matrix solution can then be used to transform any other color measured by the colorimeter on that specific display into accurate and corrected chromaticity coordinates and luminance values for any color within the gamut of the display primaries.

A matrix developed for one type of display will not work on another display of a different technology because the spectra are different, so the error correction will not be effective.

Because the filter-photodiode combinations for each colorimeter may be a little different than another of the same brand and model, a set of matrices needs to be developed for each colorimeter and for each display technology. For that reason, sharing correction matrices between the same colorimeter users will not work.

It's recommended to create a new meter profiling on every new display you need to calibrate. Even if it's the same display model that you have calibrated before, manufacturers occasionally change the characteristics of a display screen or backlight in the middle of a manufacturing run, without changing the model number.

It is less widely known that the color performance of LED is actually more susceptible to temperature changes, driving current and aging than traditional displays.

While the CCFL and UHP, as well as the CRT phosphors mainly decrease in brightness and change chromaticity only slightly (UHP, CCFL) or not at all (CRT), with LED the colors both decrease in brightness and considerably change the chromaticity.

The CRT contains red, green and blue phosphors that emit light when a guided electron beam hits them. These phosphors do not change color with time, but do decrease in brightness along usage, which results in both a darker display.

Because different phosphors can decrease brightness with a different pace, the white balance will also be offset with time. So, the main challenge in CRTs was to maintain the color temperature (white balance).

Lamps (CCFL or UHP) with aging or increasing temperature, the different lamp spectral peaks decrease in intensity. Their peak wavelength and peak width also shift; however, the brightness decrease of the primaries is predominant so for practical purposes we can neglect the chromaticity change.

The LED spectrum has a different behavior than both phosphors and lamps. With aging and/or higher temperature, the LED spectral peaks: a) lower; b) widen; and c) shift to different wavelengths, all at the same time. The lowering is connected to decreasing brightness. But the shift and widening means that the color also changes in chromaticity.

Moreover, the only way to control brightness of an LED is with changing the current through it. But a different current means a different local temperature, so this again changes the spectrum.

The end result of LED aging is thus: lower brightness, offset white balance, and changed chromaticity of primary colors and all other colors in between.

Because of the color performance shifting/drifting from aging, the spectra of the RGB colors can change from display to display and technology to technology, a new meter correction table will be needed for the most accurate profiling results before each calibration run of the same display.

After a meter correction profile is created, the calibration process would then be performed using the colorimeter, which performs faster throughout and has higher sensitivity at low light levels.

There 5 initial pre-calibration steps to provide the most accurate meter profile creation and calibration measurements:

Warmup times of an hour may be required before a display reaches a stability that will guarantee that the colors and luminances don’t change relative to one another during the time while the set of measurement results are obtained.

The luminance and chromaticity characteristics of displays change over the period of time that a display warms up after its powered on.

The change is most significant in the first 30 minutes, becoming less significant in the next 15 minutes. After 45 minutes of warmup, most displays, while not fully stable, continue to change only a small amount due to thermal changes.

If some of the profile measurements are made before the display becomes thermally stable, those measurements won’t accurately represent the luminance and chromaticity performance of the stabilized display.

That will cause the final calibration data to be less accurate than it could have been. Any display technology acts differently the first minutes after its powered on. CRT's/LED's are brighter and become darker, projectors do the opposite, OLED's have very low gamma initially; but after about one hour the most of displays/projectors have stable output.

Meters will require to be connected/powered from their USB plug for about 20-30 minutes before starting any measurement. The exact time depends from the temperature conditions. It can be longer if the device came from outside in winter time and will be shorter if stored at room temperature.

Usually users confuse warmup procedure and leave the meter on-contact with the display panel to become warmer from display's panel heat, which is a bad idea.

The meter must be at the room temperature, when the meter has stable temperature it will provide stable readings over the time, heat is not good for the sensors, when the meter is becoming warm, more noise is added to the sensor and this reduce the instrument S/N ratio.

Light emitted from displays is a electromagnetic radiation which will alter the temperature of the detection system of a meter, so the sensors themselves will heat up, one reason why meters like i1PRO require dark readings; to lower the drift caused by heat.

i1PRO2 has better thermal isolation due to its aluminum at the side. i1Display PRO using robust filters against prolonged exposure to heat.

basICColor DISCUS has aluminum unibody for added robustness and thermal stability and also features internal thermal compensating circuitry which will ensure that changes in the physical temperature around the device will not influence measurement results.

Konica-Minolta CS-2000 features a peltier thermo-electric cooling system to reduce dark current and improve S/N ratio.

Because of the inherent accuracy of the Four-Color-Matrix-Method, alignment of the colorimeter and spectroradiometer with the normal of the display surface can be critical. This is particularly important for displays that have significant viewing-angle changes of their properties.

Depending upon the technology, it can be beneficial to assure alignment of the measurement system to a small fraction of a degree. Related to this viewing-angle sensitivity is the subtense of the detector.

If the angular aperture is too large or if the measurement field is too large, then it may be collecting light from too wide an area where by viewing-angle deviations can influence the measurement. Similarly, for screens that are influenced by mechanical pressure such as many LCDs, contact colorimeters that place too much force on the surface can influence the measurement.

If such contact devices are used, it can be important to assure that they are touching the screen lightly enough to avoid any changes in the measurement results from mechanical contact. Additionally, any stray light entering the colorimeter from the surround must be eliminated.

When you are taking on-contact measurements of CRT displays with X-Rite i1Display PRO, a small magnet inside the ambient light cover which X-Rite is using to signaling using a Hall effect sensor what's is the cover position, it can interfere the response of the CRT display, particularly if the ambient cover is in its natural position at 180-degree away from the measuring lens.

One way of minimizing this is to swing the cover down so that it touches the display adjacent to the lens, thereby moving the magnet away from the display surface. A more thorough but inconvenient way of avoiding this problem is to unclip the ambient light cover and slide it down the cable. Another solution is to take non-contact measurements with CRT displays.

EBU TECH.3325 Publication (Methods for the Measurement of the performance of Studio Monitors) recommends the distance measuring geometry rather than the contact method.

For projectors, we have two main concerns when deciding where to place the meter. We need the meter to be far enough back that it doesn’t cast a shadow on the area of the screen we’re reading from. But we also want the meter to be as close to the screen as possible so that we’re not adding inaccuracies such as off angle light or gain differential.

SMPTE recommends to take readings from the viewing position, but that's is not possible using consumer probes, it will require high-end spectroradiomenters with very narrow (~2.0°) field of view equipped with viewing optics (PhotoResearch/Konica-Minolta) or with laser aiming (JETI).

When you are measuring projectors, or displays with uniformity issues it's better to measure the same spot during the meter profiling procedure. Each meter has its own Field Of View (FOV) so their optics see different diameter area of pixels during a measurement.

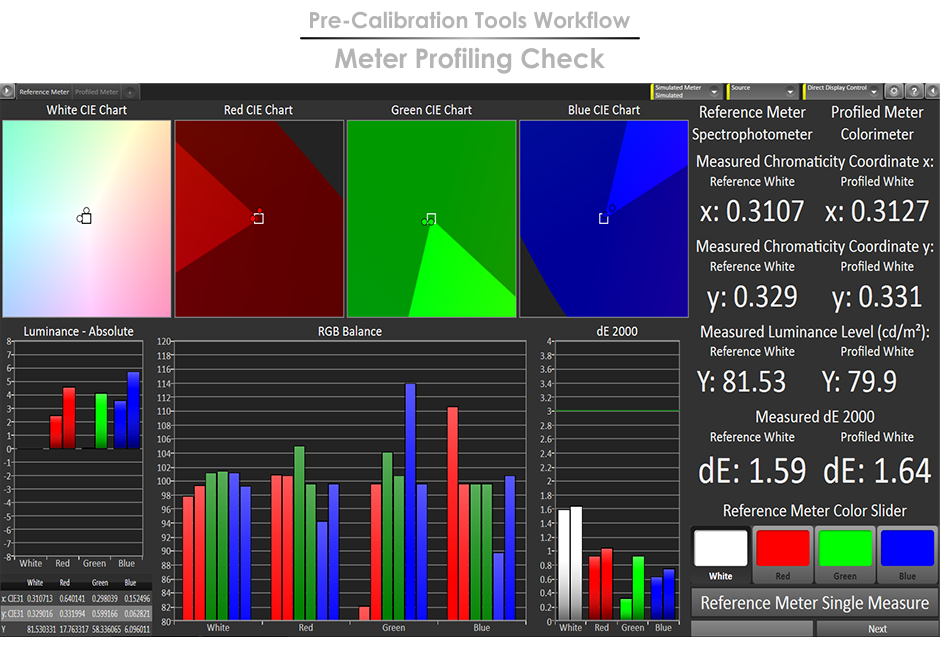

When you create a four-color meter matrix correction table, it's recommended to always check if the calculated correction table is accurate and then start to use that correction table for all your other display calibration measurements.

A lot of users very familiar with the meter profiling procedure will be surprised when they will perform that verification test for their first time; they may be found that their generated meter correction table is not so accurate.

NIST's accepted tolerances are below xy +-0.001 and +-1.5% Luminance when you will compare the 4 color (W,R,G,B) xyY chromaticity and luminance readings between the reference meter used (spectrophotometer/spectroradiometer) and profiled colorimeter (colorimeter with four color matrix correction loaded).

Sometimes it will be required to re-perform the meter profiling procedure a second time to get better verification results with tighter tolerances.

For CalMAN 5 users of Ted's LightSpace CMS Calibration Disk, we provide access to various workflows which are including a Meter Profiling Check layout page to give the capability to perform a meter profiling accuracy verification:

This website uses a Comodo Positive SSL certificate to protect online transactions with the highest strength encryption.